As we enter 2026, commercial property owners, facility managers, and business operators across New South Wales face increasingly stringent compliance requirements for building systems. A comprehensive facility compliance audit is no longer optional—it’s a critical component of risk management, legal compliance, and operational efficiency. With the recent launch of the BCNSW eCert portal in December 2025 and evolving Australian Standards for electrical, plumbing, and roofing systems, understanding how to conduct thorough facility compliance audits has never been more important.

This complete guide provides facility managers, commercial property owners, and operations directors with a strategic framework for conducting facility compliance audits across plumbing, electrical, and roofing systems. Whether you manage office buildings, retail spaces, industrial facilities, or multi-tenant commercial properties in Sydney, Central Coast, or anywhere across NSW, this guide delivers actionable insights to ensure your facility meets 2026 compliance standards.

Why Facility Compliance Audits Are Critical for NSW Commercial Properties in 2026

The commercial property landscape in NSW continues to evolve with heightened regulatory oversight, increased liability exposure, and growing tenant expectations for safety and sustainability. Facility compliance audits serve multiple strategic purposes:

Legal and Regulatory Compliance

NSW commercial properties must comply with multiple regulatory frameworks including the National Construction Code (NCC), AS/NZS 3000 electrical standards, plumbing codes, and occupational health and safety regulations. Non-compliance can result in fines exceeding $50,000, operational shutdowns, invalidated insurance claims, and personal liability for building owners and facility managers.

Risk Management and Liability Protection

Regular facility compliance audits identify potential hazards before they cause injuries, property damage, or business interruption. With commercial general liability insurance premiums rising 12-18% annually, documented compliance audits demonstrate due diligence and can significantly reduce premium costs while protecting against claims.

Operational Efficiency and Asset Longevity

Preventive maintenance identified through compliance audits extends the service life of expensive building systems by 30-50%. An HVAC system properly maintained through regular audits can last 20+ years versus 10-12 years without systematic oversight. Electrical systems maintained to compliance standards reduce energy consumption by 15-25%, directly impacting operational costs.

Tenant Satisfaction and Property Value

Commercial tenants increasingly demand proof of building compliance and safety. Properties with documented compliance programs command 8-12% higher rental rates and experience 40% lower vacancy rates. When selling commercial property, comprehensive compliance documentation can increase sale prices by $500,000+ for mid-sized buildings.

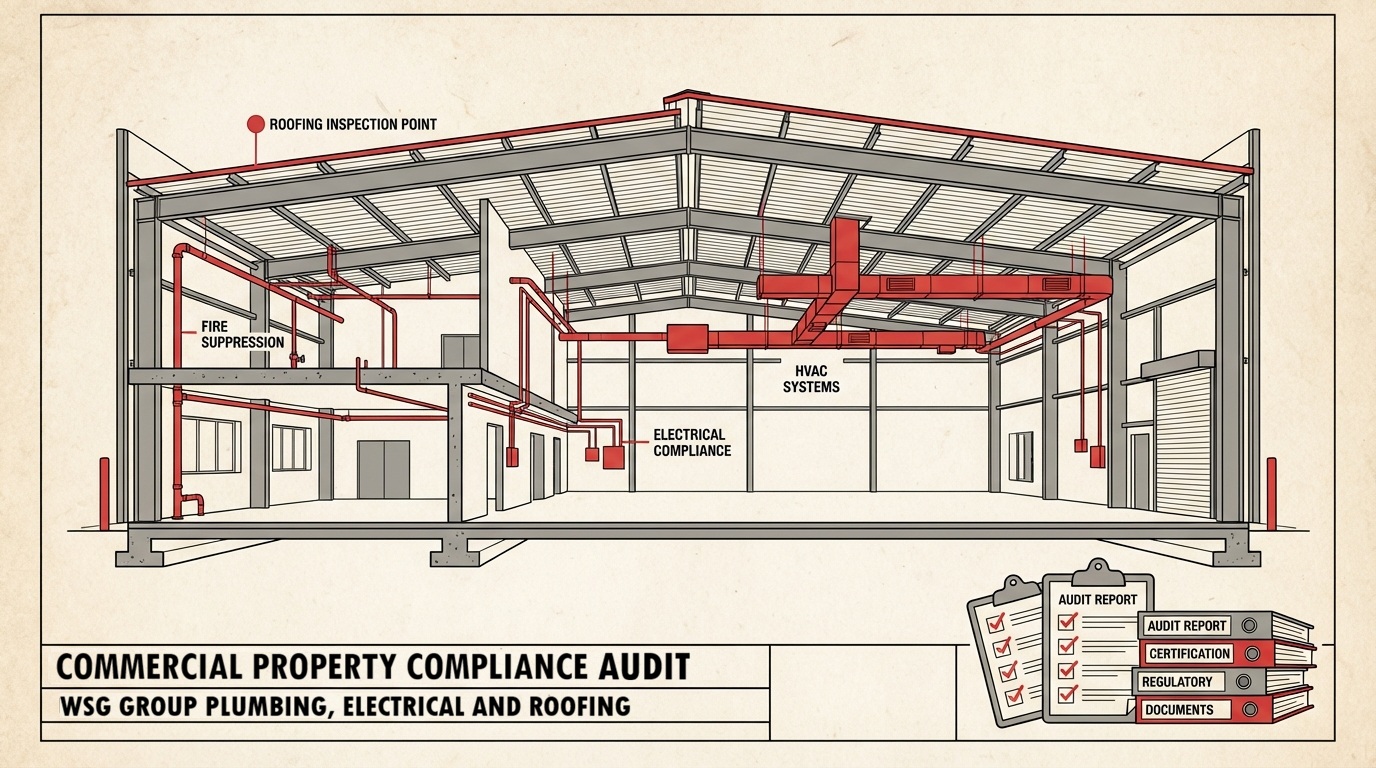

Understanding the Three Pillars: Plumbing, Electrical, and Roofing Compliance

Effective facility compliance audits focus on three critical building systems that present the highest risk, regulatory scrutiny, and maintenance requirements. Each system requires specialized knowledge, licensed contractors, and specific documentation protocols.

Plumbing System Compliance Requirements

Commercial plumbing systems in NSW must meet standards set by the Plumbing Code of Australia (PCA) and relevant Australian Standards. Key compliance areas include:

- Backflow Prevention Devices: Annual testing and certification required for all commercial properties connected to potable water supplies

- Hot Water Temperature Control: Thermostatic mixing valves required to prevent scalding (maximum 50°C at outlets)

- Grease Trap Compliance: Commercial kitchens must maintain and document regular grease trap servicing

- Water Efficiency Standards: WELS-rated fixtures required in new installations and major renovations

- Emergency Shut-off Accessibility: Clearly marked and accessible water isolation points

- Cross-Connection Control: Proper air gaps and backflow devices on all connections

- Drainage System Capacity: Adequate sizing and grade for waste water removal

- Gas Fitting Compliance: Licensed gas fitters required for all gas appliance installations and repairs

Electrical System Compliance Requirements

Electrical compliance represents the most heavily regulated aspect of commercial building systems. The AS/NZS 3000:2018 Wiring Rules establish minimum safety standards. Critical compliance requirements include:

- Electrical Safety Certificates: Certificate of Compliance for Electrical Work (CCEW) required for all installations, modifications, and major repairs

- Safety Switch (RCD) Protection: Mandatory on all power circuits and socket outlets in commercial premises

- Switchboard Compliance: Modern switchboards with appropriate circuit protection and clear labeling

- Emergency Lighting Systems: Compliant emergency and exit lighting with 90-minute battery backup

- Test and Tag Programs: Regular testing and tagging of portable electrical equipment (frequency based on environment)

- Electrical Installation Condition Reports: Periodic inspection recommended every 5 years for commercial properties

- Thermal Imaging Inspections: Identifying hot spots and potential failures in electrical distribution systems

- BCNSW eCert Portal Registration: All electrical work certificates must be submitted through the new portal

Roofing and Waterproofing Compliance

While roofing compliance receives less regulatory attention than plumbing and electrical systems, failures can cause extensive property damage, business interruption, and liability claims. Critical compliance areas include:

- Roof Membrane Integrity: Regular inspection for ponding water, cracks, blistering, and seam separation

- Gutter and Downpipe Capacity: Adequate sizing per Australian Standard AS/NZS 3500.3 for rainwater drainage

- Fall Arrest Systems: Compliant anchor points and safety rails for roof access (AS/NZS 1891.4)

- Fire Rating Compliance: Appropriate roof construction for the building classification and fire resistance level

- Penetration Sealing: Proper flashing and waterproofing around all roof penetrations

- Regular Maintenance Documentation: Documented inspection and maintenance programs

- Storm Damage Assessment: Post-storm inspections to identify and document damage for insurance claims

- Waterproofing Warranties: Maintaining manufacturer warranties through compliant installation and maintenance

Step-by-Step Facility Compliance Audit Process

Conducting effective facility compliance audits requires a systematic approach that combines regulatory knowledge, technical expertise, and thorough documentation. This proven methodology ensures comprehensive coverage while maximizing efficiency.

Phase 1: Pre-Audit Planning and Documentation Review (Week 1)

Before conducting physical inspections, gather and review existing documentation:

- 1. Collect all previous inspection reports, compliance certificates, and maintenance records

- 2. Review building plans, specifications, and as-built documentation

- 3. Identify applicable regulatory requirements and Australian Standards

- 4. Determine required testing equipment and specialized contractors

- 5. Schedule access to all areas including roofs, electrical rooms, and mechanical spaces

- 6. Notify tenants and coordinate inspections to minimize business disruption

- 7. Prepare audit checklists specific to your facility type and systems

- 8. Establish documentation protocols and reporting formats

Phase 2: Visual Inspection and Non-Invasive Testing (Week 2)

Systematic walk-through inspection of all building systems:

- Electrical Systems: Visual inspection of switchboards, distribution boards, lighting, power points, and emergency systems

- Plumbing Systems: Check for leaks, corrosion, proper labeling, accessible shut-offs, and backflow devices

- Roofing: Inspect membrane condition, drainage, penetrations, and structural support

- Documentation: Photograph conditions, label systems, note serial numbers and installation dates

- Safety Hazards: Identify immediate risks requiring urgent attention

- Tenant Interviews: Gather feedback on system performance and ongoing issues

Phase 3: Invasive Testing and Specialist Assessments (Week 3)

Engage licensed contractors for specialized testing:

- Licensed Electrician: Conduct electrical installation condition report with testing of RCDs, insulation resistance, earth continuity, and polarity

- Licensed Plumber: Test backflow prevention devices, check hot water temperature control, inspect drainage systems

- Thermal Imaging: Identify electrical hot spots, water leaks, and building envelope deficiencies

- Roof Consultant: Conduct invasive moisture testing if visual inspection indicates potential issues

- Test and Tag: Complete testing and tagging of all portable electrical equipment

- Air Quality Testing: If HVAC concerns identified during visual inspection

Phase 4: Analysis, Reporting, and Action Planning (Week 4)

Compile findings into comprehensive compliance audit report:

- Executive Summary: High-level overview of compliance status and critical issues

- Compliance Matrix: Detailed checklist showing compliance status for each requirement

- Risk Assessment: Prioritize identified issues by safety risk, compliance urgency, and financial impact

- Photographic Documentation: Include clear photos of all deficiencies with annotations

- Remediation Plan: Specific recommendations with estimated costs and timeframes

- Certification Requirements: Identify which items require licensed contractor certification

- Ongoing Maintenance Program: Establish regular inspection and maintenance schedules

- Budget Planning: Multi-year capital planning for major system replacements

Commercial facility compliance audit checklist maintenance inspection documentation plumbing electrical systems

Critical Compliance Checkpoints: What Auditors Look For

Regulatory inspectors, insurance assessors, and due diligence auditors focus on specific high-risk items during facility inspections. Understanding these critical checkpoints ensures your internal compliance audits address the areas that matter most.

High-Priority Electrical Compliance Items

- RCD Testing Documentation: Evidence of regular (quarterly or annual) safety switch testing

- Switchboard Labeling: Clear circuit identification and warnings

- Exit and Emergency Lighting: Functional tests and battery duration verification

- Electrical Certificates: Current CCEWs for all work completed since last audit

- Test and Tag Currency: All portable equipment tagged within required timeframe

- Exposed Wiring: Immediate correction of any exposed conductors or damaged insulation

- Overloaded Circuits: Evidence of proper load management and distribution

- As-Built Documentation: Updated electrical drawings reflecting current installation

High-Priority Plumbing Compliance Items

- Backflow Device Testing: Annual test certificates from licensed plumbers

- Hot Water Temperature: Compliance with 50°C maximum at outlets (anti-scald protection)

- Visible Leaks: Any active leaks represent both compliance and insurance issues

- Gas Certificate: Current gas compliance certificate if gas appliances present

- Grease Trap Records: Documentation of regular servicing (monthly for most commercial kitchens)

- Water Shut-off Access: Clear labeling and unobstructed access to isolation valves

- Drainage Capacity: Evidence that drainage systems handle peak loads without backup

- Cross-Connection Control: Proper air gaps on equipment connected to water supply

High-Priority Roofing and Building Envelope Items

- Ponding Water: Any standing water indicating drainage deficiencies

- Membrane Damage: Visible cracks, blisters, or seam separation

- Penetration Sealing: Proper flashing around all roof penetrations

- Gutter Capacity: Adequate sizing and clear of debris accumulation

- Fall Protection: Compliant anchor points if regular roof access required

- Storm Damage: Documentation and repair of any weather-related damage

- Structural Integrity: No sagging or deflection indicating structural issues

- Warranty Compliance: Adherence to manufacturer maintenance requirements

Common Compliance Failures and How to Avoid Them

Based on thousands of commercial facility audits across NSW, certain compliance failures appear repeatedly. Understanding these common pitfalls enables proactive prevention.

Documentation Gaps: The Silent Compliance Killer

The most common compliance failure isn’t actual safety issues—it’s inadequate documentation. Work may be compliant and performed by licensed contractors, but without proper certification and records, properties fail audits and face regulatory penalties.

Prevention Strategy: Implement a centralized compliance documentation system. Require certificates of compliance for ALL work performed. Maintain a digital archive with automatic expiry alerts for time-limited certifications like backflow device testing and emergency lighting inspections.

Deferred Maintenance Creating Compliance Cascades

Minor maintenance issues, when deferred, often create multiple compliance violations. A small roof leak ignored becomes water damage affecting electrical systems, creating both plumbing and electrical compliance issues plus mold remediation requirements.

Prevention Strategy: Establish clear maintenance response protocols with defined timeframes. Small leaks receive same-day response. Electrical anomalies trigger immediate licensed electrician inspection. Documented response demonstrates compliance intent even if full resolution requires longer timeframes.

Unlicensed Work and Shortcuts

Cost pressure sometimes leads to unlicensed contractors or handyman services performing work requiring licensed trades. This creates multiple problems: work fails to meet standards, no compliance certification issued, insurance coverage voided, and significant liability exposure.

Prevention Strategy: Implement strict contractor pre-qualification. Require license verification, insurance certificates, and safety documentation before any work authorization. The cost savings from unlicensed work are insignificant compared to the risk exposure.

Incomplete Tenant Modification Documentation

Commercial tenants often make modifications during fit-out without proper documentation or landlord approval. When the tenant vacates, the property owner inherits non-compliant systems without documentation.

Prevention Strategy: Lease agreements must require landlord approval for all building system modifications. Require tenants to provide compliance certificates for any approved work. Conduct compliance audits at lease commencement and termination.

Building Your Ongoing Compliance Program

Single compliance audits provide valuable snapshots, but sustained compliance requires systematic ongoing programs. The most effective facility compliance programs incorporate three components: regular inspections, preventive maintenance, and documentation management.

Establishing Inspection Frequencies

Different building systems require different inspection intervals based on regulatory requirements, risk levels, and system criticality:

| System Component | Inspection Frequency | Compliance Requirement |

| RCD Safety Switches | Quarterly (high-risk) or Annually | AS/NZS 3000 recommendation |

| Emergency Lighting | Monthly (function test), Annual (duration) | AS/NZS 2293.2 |

| Backflow Prevention Devices | Annual testing + certification | Plumbing Code of Australia |

| Portable Electrical Equipment | Annual (office) to 3-monthly (construction) | AS/NZS 3760 |

| Hot Water Temperature | Monthly testing at outlets | AS 3500.4 |

| Roof and Gutters | Quarterly visual, Annual detailed | Best practice / insurance requirement |

| Switchboard Thermal Imaging | Annual or bi-annual | Best practice (prevent failures) |

| Electrical Condition Report | Every 5 years | AS/NZS 3000 recommendation |

| Drainage System | Annual inspection + CCTV every 3-5 years | Preventive maintenance |

| Fire Safety Systems | Per Fire Safety Statement schedule | Environmental Planning & Assessment Regulation |

Preventive Maintenance Integration

Compliance audits identify what needs attention; preventive maintenance programs ensure systematic follow-through. Effective programs include:

- Scheduled Service Contracts: Annual agreements with licensed electricians, plumbers, and roofing contractors for regular inspections

- Condition-Based Monitoring: Use thermal imaging, vibration analysis, and other diagnostic tools to identify developing issues

- Parts and Materials Planning: Maintain critical spare parts inventory and pre-approved suppliers for rapid response

- Seasonal Preparation: Pre-summer roof inspections, pre-winter drainage clearing, pre-storm emergency preparedness

- Vendor Management: Cultivate relationships with qualified contractors for priority response and competitive pricing

- Training Programs: Ensure facility staff understand inspection requirements and early warning signs

Cost-Benefit Analysis: ROI of Systematic Compliance Programs

Facility compliance programs require investment in inspections, testing, documentation, and maintenance. However, the return on investment significantly exceeds costs when considering risk mitigation, operational efficiency, and asset preservation.

Direct Financial Benefits

Based on commercial property management data across Sydney and Central Coast:

- Insurance Premium Reduction: 10-15% lower premiums with documented compliance programs

- Energy Cost Savings: 15-25% reduction through optimized electrical system maintenance

- Emergency Repair Avoidance: 60-70% reduction in costly emergency after-hours repairs

- Extended Asset Life: 30-50% longer service life for major building systems

- Reduced Vacancy: 40% lower vacancy rates due to system reliability and tenant confidence

- Higher Rental Rates: 8-12% premium rental rates for buildings with documented compliance

Risk Mitigation Value

The avoided costs of compliance failures often exceed the total compliance program investment:

- Regulatory Penalties: NSW Fair Trading fines for electrical work without certificates start at $5,500 per offense

- Denied Insurance Claims: Non-compliant systems can void insurance coverage entirely, exposing owners to full liability

- Personal Injury Claims: Electrical injuries in commercial properties result in average claims of $250,000-$500,000

- Business Interruption: System failures causing tenant business interruption can trigger substantial damages claims

- Property Damage: Undetected roof leaks causing interior damage average $45,000 in commercial properties

- Litigation Costs: Defending compliance-related litigation averages $80,000-$150,000 even when successful

Sample ROI Calculation: Mid-Sized Commercial Property

Consider a 2,500 square meter commercial office building in Sydney:

Annual Compliance Program Investment:

• Quarterly electrical inspections: $2,400

• Annual electrical condition report: $3,500

• Annual plumbing compliance inspection: $1,800

• Backflow device testing: $600

• Roof inspection (quarterly): $2,000

• Test and tag program: $1,500

• Documentation management system: $1,200

• Total Annual Investment: $13,000

Annual Returns:

• Insurance premium reduction (12%): $4,800

• Energy cost reduction (18%): $7,200

• Avoided emergency repairs (estimated): $8,500

• Extended equipment life (annualized): $6,000

• Total Annual Returns: $26,500

• Net Annual Benefit: $13,500

• ROI: 204%

This analysis excludes the risk mitigation value of avoided regulatory penalties, insurance claim denials, and liability exposure—benefits that alone justify the compliance investment.

Selecting the Right Compliance Audit Partner

While internal facility staff can conduct routine inspections, comprehensive compliance audits require specialized expertise across multiple trades. Selecting the right compliance audit partner significantly impacts program effectiveness.

Essential Qualifications and Licensing

Compliance audit providers must hold appropriate licenses and insurance:

- Licensed Electrical Contractors: Level 2 or Restricted licenses as appropriate

- Licensed Plumbing Contractors: Full plumbing license with backflow testing credentials

- Building Consultants: Experience in commercial building codes and Australian Standards

- Professional Indemnity Insurance: Minimum $10 million coverage

- Public Liability Insurance: Minimum $20 million coverage for commercial work

- Workers Compensation: Full coverage for all personnel

- Thermal Imaging Certification: Qualified thermographers for electrical inspections

Service Scope Considerations

The most efficient compliance audits utilize multi-trade contractors who can assess all building systems comprehensively:

- Integrated Service Offering: Single contractor providing plumbing, electrical, and roofing assessments reduces coordination complexity

- 24/7 Emergency Response: Compliance audits often identify issues requiring urgent attention

- Commercial Experience: Residential contractors may lack commercial building expertise and regulatory knowledge

- Geographic Coverage: Ensure service coverage across all property locations

- Reporting Capabilities: Clear, actionable reports with photographic documentation and prioritized recommendations

- Ongoing Maintenance Capability: Contractors who can both identify and remediate issues streamline the process

Technology and Tools for Modern Compliance Management

Digital tools and modern diagnostic technology dramatically improve compliance audit efficiency, accuracy, and documentation quality.

Computerized Maintenance Management Systems (CMMS)

CMMS platforms provide centralized compliance documentation, automated scheduling, and regulatory tracking. Leading systems offer mobile applications enabling technicians to capture inspection data, photos, and certifications directly from the field, automatically populating compliance databases.

Advanced Diagnostic Technologies

- Thermal Imaging Cameras: Identify electrical hot spots, water leaks, and building envelope deficiencies non-invasively

- Drone Roof Inspections: Comprehensive roof documentation without safety risks or access challenges

- CCTV Drainage Inspection: Video documentation of underground drainage systems identifies issues before catastrophic failures

- Portable Appliance Testers: Automated test and tag equipment with digital record-keeping

- Electrical Test Equipment: Advanced testing devices providing detailed compliance verification data

- Moisture Meters and Leak Detection: Pinpoint hidden water infiltration before visible damage appears

Cloud-Based Documentation Systems

Cloud platforms ensure compliance documentation remains accessible, backed up, and automatically organized. Look for systems offering:

- Automatic certificate expiry alerts for time-limited compliance items

- Integration with contractor management systems

- Tenant portal access for transparency and communication

- Audit trail documentation for regulatory inquiries

- Mobile access for facility managers and contractors

- Automated reporting for executive oversight and board reporting

Preparing for Regulatory Inspections and Due Diligence Audits

Proactive facility compliance programs pay immediate dividends when facing regulatory inspections, insurance assessments, or property sale due diligence audits.

Regulatory Inspection Preparation

NSW Fair Trading, WorkSafe, and local councils conduct routine and complaint-driven inspections. Preparation includes:

- Centralize all compliance certificates and inspection reports in readily accessible format

- Ensure all required compliance certificates are current and properly filed

- Review property against known regulatory focus areas (electrical safety, backflow prevention)

- Conduct pre-inspection walk-through to identify any obvious deficiencies

- Brief facility staff on inspection protocols and information access

- Document all ongoing remediation work with timelines and completion commitments

- Maintain professional demeanor—cooperative engagement typically results in better outcomes

Due Diligence Audit Readiness

Property sales, refinancing, and major tenant lease negotiations trigger comprehensive due diligence audits. Properties with systematic compliance programs complete due diligence faster and receive higher valuations:

- Organize comprehensive compliance data room with all certificates, reports, and maintenance records

- Prepare executive summary of building systems condition and compliance status

- Document capital expenditure plans and depreciation schedules

- Provide warranty documentation and as-built drawings

- Compile operating expense history demonstrating efficient facility management

- Highlight compliance program investments and resulting risk mitigation

- Offer facility tours with key maintenance contractors available for questions

Conclusion: Building a Culture of Compliance Excellence

Facility compliance audits represent far more than regulatory checkbox exercises. When executed systematically, they become strategic tools for risk management, operational excellence, and asset value optimization. Commercial properties across Sydney, Central Coast, and throughout NSW that embrace comprehensive compliance programs consistently outperform competitors across every meaningful metric: lower operating costs, higher tenant satisfaction, reduced insurance premiums, and superior investment returns.

The transition from reactive maintenance to proactive compliance management requires initial investment in professional audits, systematic documentation, and ongoing preventive maintenance. However, as demonstrated throughout this guide, the return on investment exceeds 200% annually while simultaneously reducing risk exposure that could potentially exceed the entire property value.

As we progress through 2026, regulatory oversight continues intensifying, insurance requirements become more stringent, and tenant expectations elevate. Commercial property owners and facility managers who establish robust compliance programs today position their properties for sustained success while those who defer action face compounding risks and costs.

Whether you manage a single commercial building or a portfolio of properties across NSW, the framework outlined in this guide provides a proven pathway to compliance excellence. The investment in professional facility compliance audits, licensed contractor relationships, and systematic documentation programs pays dividends immediately and compounds over time.

Ready to conduct a comprehensive facility compliance audit for your NSW commercial property? WSG Group provides integrated plumbing, electrical, and roofing compliance audits backed by 70+ years of experience serving Sydney and Central Coast commercial properties. Our licensed professionals deliver thorough inspections, clear actionable reports, and complete remediation services—all from one trusted partner. Contact WSG Group at 1800 186 597 for a free consultation and discover how systematic compliance programs protect your investment, reduce operational costs, and ensure regulatory confidence.

Frequently Asked Questions About Facility Compliance Audits

Q1: How much does a facility compliance audit cost for a commercial property in NSW?

A1: Comprehensive facility compliance audits for commercial properties in NSW typically range from $2,500-$8,000 depending on building size, complexity, and scope. A 1,000 square meter office building averages $3,500-$4,500, while larger industrial facilities may exceed $10,000. Multi-trade contractors offering integrated plumbing, electrical, and roofing assessments typically provide better value than coordinating separate contractors. The audit investment is generally recovered within 12 months through identified energy savings, insurance premium reductions, and avoided emergency repairs.

Q2: How often should commercial properties conduct facility compliance audits?

A2: Most commercial properties should conduct comprehensive facility compliance audits annually, with more frequent targeted inspections for specific systems. Electrical systems warrant quarterly RCD testing and annual condition assessments. Plumbing systems require annual backflow device testing and general inspection. Roofing benefits from quarterly visual inspections and annual detailed assessments. High-risk environments, older buildings, and properties with complex systems may require semi-annual comprehensive audits. Establishing a systematic inspection schedule based on regulatory requirements and risk assessment ensures consistent compliance while optimizing maintenance investments.

Q3: What are the penalties for non-compliance with NSW building regulations?

A3: NSW regulatory penalties for building compliance violations vary significantly based on offense severity and circumstances. Electrical work performed without proper certification can result in fines starting at $5,500 per offense for individuals and substantially higher for companies. Serious electrical safety violations can trigger prosecution with penalties exceeding $50,000 plus legal costs. Beyond direct fines, non-compliance can void insurance coverage, expose property owners to personal injury liability claims averaging $250,000-$500,000, and result in occupation certificates being revoked requiring building evacuation until compliance achieved. The financial and operational impacts of non-compliance far exceed systematic compliance program costs.

Q4: Can I conduct facility compliance audits internally or must I hire external contractors?

A4: While facility staff can perform routine visual inspections and basic maintenance checks, comprehensive compliance audits require licensed contractors for specific regulated activities. Electrical testing and certification must be performed by licensed electricians who can issue Certificates of Compliance for Electrical Work (CCEW). Backflow device testing requires licensed plumbers with specialized credentials. Some inspection activities like thermal imaging and test-and-tag can be performed by trained facility staff using proper equipment, but certification and compliance documentation require appropriate licenses. The most effective approach combines regular internal inspections with annual professional comprehensive audits by multi-trade contractors providing both assessment and remediation capabilities.

Q5: What documentation should result from a facility compliance audit?

A5: Comprehensive facility compliance audits should produce detailed written reports including: executive summary of compliance status and critical issues; system-by-system inspection findings with photographic documentation; compliance matrix showing conformance with applicable regulations and standards; risk assessment prioritizing identified issues by safety risk, compliance urgency, and financial impact; remediation plan with specific recommendations, estimated costs, and timeframes; all applicable compliance certificates (CCEW for electrical work, plumbing certificates, backflow testing certificates); updated as-built documentation reflecting current conditions; and ongoing maintenance recommendations with suggested inspection schedules. All documentation should be provided in both physical and digital formats for easy accessibility and backup.

Q6: How does the BCNSW eCert portal affect facility compliance audits?

A6: The BCNSW eCert portal launched in December 2025 streamlines how specialist trades complete and submit compliance certificates for electrical, plumbing, and other regulated work in NSW. For facility managers, this means all electrical work certificates (CCEWs) and plumbing compliance documentation must be registered through the portal. During facility compliance audits, auditors can verify certificate authenticity through the portal rather than relying solely on paper documentation. Property owners should ensure all contractors use the portal for certificate submission and maintain portal access credentials to retrieve documentation for due diligence audits and regulatory inspections. The digital system reduces documentation gaps that historically caused compliance audit failures.

Q7: What role does facility compliance play in commercial property insurance?

A7: Commercial property insurance increasingly requires documented compliance programs as a condition of coverage. Insurers recognize that properties with systematic inspection and maintenance programs present substantially lower risk. Many insurers now offer premium discounts of 10-15% for properties providing evidence of regular compliance audits and preventive maintenance programs. Conversely, insurance claims for incidents involving non-compliant systems face increased scrutiny and potential denial. Properties experiencing electrical fires in systems without current compliance certificates or water damage from uninspected plumbing systems often find coverage limited or excluded. Documented compliance programs not only reduce insurance costs but ensure full coverage when incidents occur, protecting property owners from catastrophic financial exposure.